Products

Agitator

At Metal Fab, we manufacture top quality engineered to order agitator and mixers to serve many industries decades of technical expertise and processes built around quality and compliance, the value of our agitator and mixers ensures the integrity of yours. Our MetalFab top-entering agitators leads the industry in performance and cleanability.

They are the next generation of quality, performance, cleanability, and value for any application requiring superior sanitary mixing. Our agitator are specifically designed for demanding chemical, food pharmaceutical and biotechnical mixing application.

Our stainless steel drives are available in direct, parallel, and right angle with unlimited impeller choice and clamp-on, tri-clamp, and flange mounted option. From simple to complex, our engineers will design a system for your specific application.

- All stainless drives – complete with inverter duty motor, reduction gear and pedestal

- Versatile drive motor mounting configuration that include direct drive, in line parallel or right angle

- Unlimited impeller availability including classic turbines, high shear and custom design.

- Mechanically polished finishes and final electro-polishing available to match any product contact specification

- Mixers for low and High viscosity liquid.

Conveyors

Bucket Elevators are a simple but effective method of elevating free flowing and semi- free flowing bulk materials. MetalFab bucket elevators operates in a wide variety of markets from grains, feeds, foods to oilseeds, biomass waste, minerals, solid chemicals. Metalfab Bucket Elevators are capable of handling most free flowing materials as well as many material with poor flow a characteristics.

- Belt width up to 8’ wide made with

- Conveyor types includes Troughing, flat roller and slider designs

- Deep channel Frame construction and truss frame conveyor

- Idlers, impact rollers, guide rollers, deflection / return roller assemblies with variable sizes

- Belt cleaner, scrapers and covers are available in wide ranges.

- Heavy-duty Pulley, snub pulleys assemblies.

- Fixed or Radial support structure

- Magnetic pulley Assemblies

- Walkway & Service platforms

- Hopper and side skirt options

- Variable Drive options

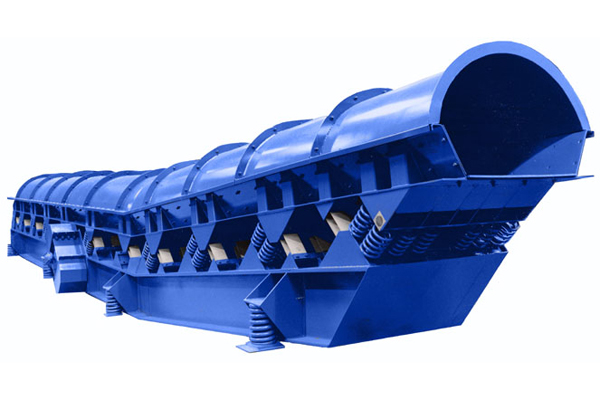

All of Metalfab‘s vibrating machines are custom built to provide exceptional dispersion over the deck while providing smooth and reliable operation. Metalfab’s, machine are heaviest in the industry for material handling with low maintenance. The application include shear take-away, under-mill, sorting and picking, batch feeders and metering, plus many others. These machine are engineered to be extremely versatile with a variety of products.

- Serve duty construction

- Coil and rubber springs option

- Rotary Electric Drives

- Eccentric Oscillator Drive

- Heavy duty Rocker Arm assemblies

- Optional load hopper

- Variable speed controls

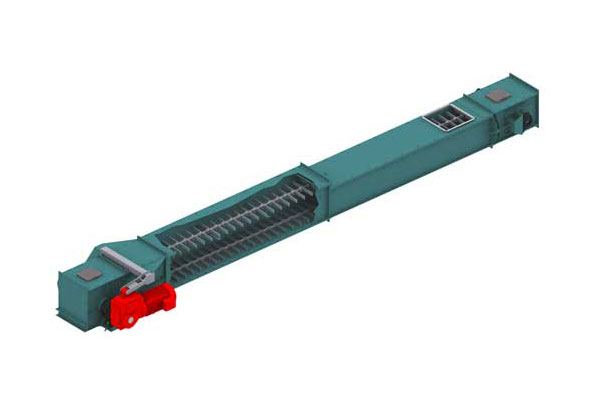

MetalFab screw conveyors are used in many industries to transport and distribute flow able bulk solid materials. While one of the oldest and simplest mean conveying products, they are compact, versatile and economical. With certain modification and/or variations in the mechanical arrangements, screw may be used to mix, blend or agitate. In application where close control of material flow is critical, the screw conveyor may be used as a highly accurate metering device.

Metalfab manufactures a wide range of screw conveyors with different styles classified as spiral screw conveyor, sectional screw conveyor, single cut flight, ribbon flight, standard pitch with paddles, screw cut and folded flight, single flight short pitch, single flight large pitch, single fight variable pitch, step flight, van paddle conveyor, that suits for various applications.

- Helical or sectional fighting intermittently welded on centre pipe

- Trough in modular flanged sections in standard lengths

- Trough feet or saddles for intermediate support

- Flanged end bearing assemblies protected by shaft seal

- Bolted trough covers

- Square or round inlet/outlet spouts with industrial standard drilled flanges.

- The Screw conveyor drive mounted on inlet or outlet end.

- 2 bolt coupling

- Intermediate hanger bearing, self-lubricating or greased types.

- Prime paint standards

Bucket Elevators are a simple but effective method of elevating free flowing and semi- free flowing bulk materials. MetalFab bucket elevators operates in a wide variety of markets from grains, feeds, foods to oilseeds, biomass waste, minerals, solid chemicals. Metalfab Bucket Elevators are capable of handling most free flowing materials as well as many materials with poor flow a characteristics.

- Centrifugal Discharge elevator

Either series is available with buckets mounted on a chain or belt and will handle free-flowing materials with small to medium size lumps. The standard inlet chute and standard curved bottom plate direct the material into the buckets and reduce the “digging” action. The speed of the elevator is sufficient to discharge the material by centrifugal force.

- Continuous Discharge elevator

Either series is available with buckets mounted on a chain or belt and will handle free-flowing material, sluggish material or materials that are abrasive. The closely spaced fabricated buckets, with extended sides, form a “chute” to direct material into the bucket. At the discharge, the bucket configuration allows the material to discharge by gravity over the back of the proceeding bucket.

- High Speed centrifugal grain

High-speed centrifugal discharge bucket elevators are specially designed to economically handle grain and other free-flowing materials. These elevators are not self-supporting therefore, intermediate supports must be provided by others.

- Continuous Discharge – Super Capacity

Continuous Discharge Super Capacity type elevators are offered with style “SC” continuous discharge buckets mounted between two strands of chain. These units are used where higher capacities, severe duty, or higher shaft centers are required. Housing construction is heavy duty for severe service.

About Roller conveyors we believe in offering you the best product and being your partner to better solution. Considering an effective means of transporting materials and goods around a factory roller conveyors are fast and easy. Our standard steel roller diameter are ¾” to 3 ½”. Custom designs are available for special requirements like turning corners, transfer, change speed, stop accumulate, sorting, pivoting, reversing and diverting. The conveyors have a standard carbon steel metal or metallic silver powdered coated or stainless steel finish.

- Gravity or chain driven power rollers

- Change speed direction, orientation

- Guard rails and custom finish

- Efficient and fast

- Backups occurs rarely

- Require less power

- Easy side loading en route

- Adjusting Floor support

- Locking caster wheels

MetalFab drag chain conveyors are the most efficient form of material handling for high volume conveying. In horizontal applications the MetalFab drag chain conveyors can handle upto 90% of the cross sectional area, resulting in smaller piece of equipment to handle the same or greater capacities over other conveying technology. These chain conveyors also provide very efficient horse power consumption keeping operating costs low. Metal Fab conveyors can handle extremely high capacities moving tons of materials per hour over relatively great distance.

- Conveyor also in dust, weather and can be gas tight

- Moves material with minimal product degradation

- Provides high hourly capacities

- Have low maintenance

- Built for 24hrs/day operation

- The chain is case –hardened alloy steel

- The segment drive sprocket design, feature tooth replacement without removal of drive shaft

- Comes complete with an auxiliary spring-loaded chain take-up

- With optional catenary take up.

- Provides abrasion-resistance construction.

Metalfab conveyor for modular chain systems are based on a close fitting flexible chain, with the ability to be constructed in many configuration. Product can travel long straight along straight , into curves or even inclined. The system can be quickly assembled from standard parts to accommodate any layouts. Compact horizontal and vertical bends allow our systems to maximize your floor spacing, while ensuring operators have clean asses and keeping production cell area to a minimum. Different chain widths and types provide smooth gentle handling, minimising product damage and with safe and reliable product flow. Standard components manufactured from anodised aluminium and moulded engineering plastic allow speed and ease of assembly while providing a clean professional result.

Metalfab industries are reputed in designing manufacturing and commissioning for a wide range of products including food, beverages, chemicals, gas bottling, pallets and many more applications

- Low Pro- suitable for light and medium weight products and width upto 200mm

- Heavy duty- Heavy duty slat chain conveyors are available both single and multi- chain varieties

- Accessories includes curves, metal or heavy duty plastic slat chain.

- Adjustable guide rails, fixed or adjustable legs

- Various chain types including plastic, stainless steel, anti-static and high grip variety.

- Product sensor

- Mobile conveyors

The Metalfab tubular drag chain conveyor is a totally enclosed design comprising of circular disc attached to a link chain or string running at low chain speed from 2’/min upto 80’/min. A link chain design act as a universal joint during product transportation in the pipe which enables a single conveyor to achieve directional changes in multiple planes, including 90deg turn. Food grade moulded discs on high grade, polished stainless steel chain for food and pharmaceutical applications in sanitary environment.

Our engineers can help you built a system based on your specific applications need. In addition to optimum conveying, the sealed tubular drag conveyor offers process efficiency, clean dust free plant environment/workers safety, excellent material integrity, low power consumption, brush box cleaning, discharge gates. Our product has following benefits

- Minimum product breakage and degradation

- Moves product horizontally and vertically in one system

- Combines Bi- directional transport with multiple inlets and discharge in one system

- Standard construction provides a dust-tight and air tight environment

- Clean-in-place system provide a total cleaning solution through efficient washing and drying

- Food grade system design

- Sanitary ultrahigh-strength hardened alloy or stainless steel chain

Metalfab offers you a continuously cycling systems are fed by conveyors to move packages, boxes, totes, and carton goods either (up to down) or (down to up) then discharge lifted or lowered materials onto adjoining conveyors section which takes the load to its next station. Equipped with either a flat platform or conveyor section, package handling lifts can become part of your internal transportation system for goods and materials. Manually loaded or conveyor fed, they help increase the speed and density of material from place to place.

- Load lift capacity up to 100lbs

- Carriage size is 3’ x 3’ max

- Vertical rise up to 25’ (standard)

- 60 to 600FPM travel speed

- Options include servo or variable frequency drive

- Perfect for use in an automated conveyorized system.

- Moves loads between conveyor levels

- Loading and unloading from three sides

- Completely self-contained, self-supporting and economical

- Durable, high quality construction ensure safe, reliable, long term performance

- Saves space and handle loads that are often transported on an inclined conveyor.

Metal Industries manufacture skate wheel conveyors in a broad range of configuration to suit many commercial applications. Skate wheel conveyors are economical and suitable for light to medium weight product with a flat base. This conveyor styles is unsuitable for drums or bagged products with unevenness of base or snagging possibilities. These conveyors are simple, robust, affordable and suits range of applications

- All steel construction for increased durability. Our galvanized wheels and side channels are typically used for permanent installation. Typically installed for adjustable H-Support

- Available in multiple standard widths

- Available in straight lengths up to 144”

- 45 and 90 deg curves available

- Numerous spur option to suit most layouts

- Lengths manufactured “to the inch” to provide flexibility for almost all situation

- End treatment includes package stops, impacts, plates, hooks and bars.

- Height adjustable H support for permanent installation. Manufactured from galvanized steel

Crusher

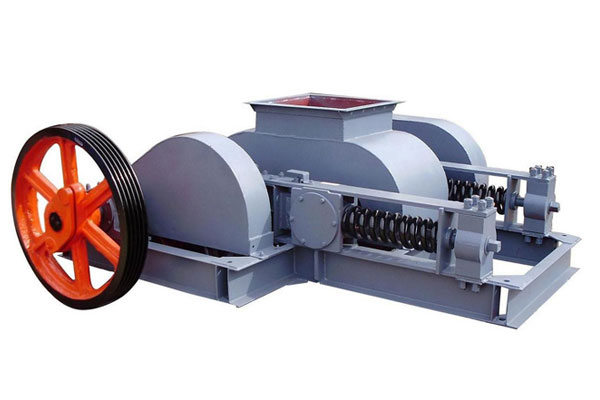

About Roller crusher we believe in offering you the best machine for crushing a variety of soft to medium-hard products. The creation of undesirable fine particles is reduced by subjecting the product to a combined shearing and pressing action. The narrow particle size distribution is achieved by controlling a combination of variables including roll speed, roll gap, differential speed, feed rate and roll surface design. Actuating device is driven by two motors, pass the triangle belt drive to Geneva wheel then drag the roller, according to the relative direction rotating, In crushing material, materials pass feed port through roller, rolling and broken, the broken finished product discharged from chassis below.

Application:

The roller crusher is widely applied in the industries of mining, building material, chemical industry, metallurgy, etc. The roller crusher can crush materials with middle hardness into secondary or fine granularity, such as crushing mineral, rocks, coke, coal, slag, and fire-proof material etc.

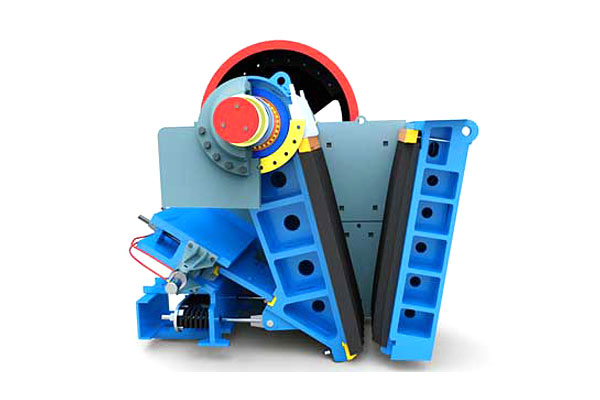

Metal Fab series jaw crusher is amongst the most typical crushing equipment. It truly is primarily applied in crushing the material with compressive strength below 320Mpa. The jaw crusher is usually utilized in the field of mining, metallurgy, road and railway construction, water conservancy, chemical industry and so on. The jaw crusher of medium and large size designed and manufactured by Metal Fab has reached the advanced level with the features of high crushing ratio, high capacity, uniformed product size, simple structure, reliable operation, easy maintenance and low operation cost.

Our Product is made up of Frame, eccentric shaft, grooved wheels, flywheels, moving jaws, side guard, toggle plate, toggle backseat, adjusting screw, returning spring, fixed jaw plates and mounting jaw plates. Toggle plate is of safety function.

- Low Noise, less dust

- Integrated steel structure are made use of for the base or bearing.

- The crushing chambers uses “V” shaped structure, so that the feeding size equal to the nominal one.

- The crushing chamber is deep and without the dead zone, increase the capacity and the output

- Lubrication system is safe and reliable, convenient to replace parts, easy to maintain.

- The outlet employs shim adjustment system, convenient and reliable and increase the flexibility of the equipment;

- The application of world-class manufacturing processes and high-tech materials.

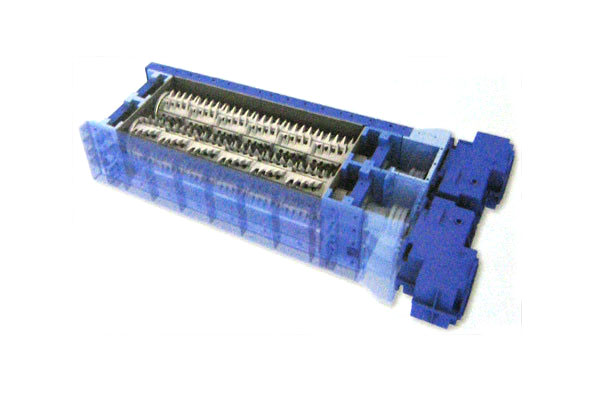

MetalFab manufactures a large variety of hammer mills to handle virtually any size reduction job. Rugged machine provides the efficiencies and economies of midair, impact crushing, grinding or shredding of diverse, materials such as: limestone, glass, diatomaceous earth, coal and lignite, clay, shale, sand, phosphorite rock, fertilizer, aluminium oxide, slags, coke, tungsten carbide, silica, bauxite, dolomite, grain, cement rock-barytes.

- High tonnage hammer mills - We manufacture a variety of big hammers mills to handle almost any high-tonnage, size reduction job.

- Rocket Hammer Mills – Our rocket hammer mill is designed for the rapid reduction of large quantities of non-abrasive material such as cereals, animal and fish by product, saw dust. Expeller cake, rags and wood pulp to fluff.

- Meteor Hammer Mills- The meteor mill is characteristics by high hammer-tip speed to permit a fine product or to obtain specific characteristic in the finished product. This mill is particularly high-quality. Fluff for the absorbent medium and non-woven fiber markets.

- Type General purpose hammer Mill- General purpose mill is a simple, rugged answer to many small and medium capacity grinding jobs

We offers powerful twin shaft crushing capabilities in a compact configuration. The unit crushes, chops, and destroy lumps, chunks, coal, cement, limestone and more, reducing them to their basic grain size. It freshens and enhances product quality and eliminate floe impediments. The twin shaft design produce a high impact force with low power usage. The unit feature a direct gear drive, one piece crushing rotor, sanitary bar grating, self cleaning action, a choice of shaft seals and a durable fabricated housing with machined flanges for easy connections to duct, hoppers, conveyors, bag un loaders or systems.

- Twin shaft shredder is with low rotation rate, low noise and large moment of torsion, powerful

- The shredder is protected from overload

- Such a machine suitable for crushing the super and thick object such as wood television, washing machine, crust of refrigeration, large pipes, forked board, tyre, packing bare etc.,

Screens

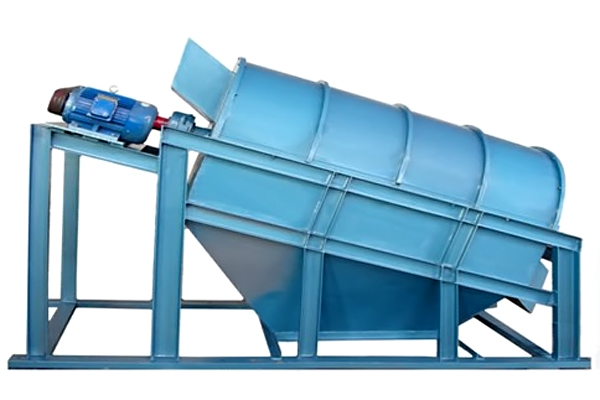

MetalFab also design and provides our clients with rotating screens, which are specially developed for efficient and economical removing of striped solids. Higher flow capacities can be used due to continuous and self cleaning effect of the rotating screens. Reckoned for low operational cost, these precisely engineered rotating screens are study.

- We offer multiple cages for separation of material as per clients requirement

- The machine has a heavy duty shaft which made from EN8 material, fitted with heavy duty bearing at both end.

- Main cage is made from heavy duty flats and square bars.

- The screens are making from spring steel material with MS or SS grade, as suitable with client application.

- The machine design with top cover and bottom discharge chute for prevent low dusting.

- The rotary screen is widely useful in mineral industry, agro products, stone industry etc.

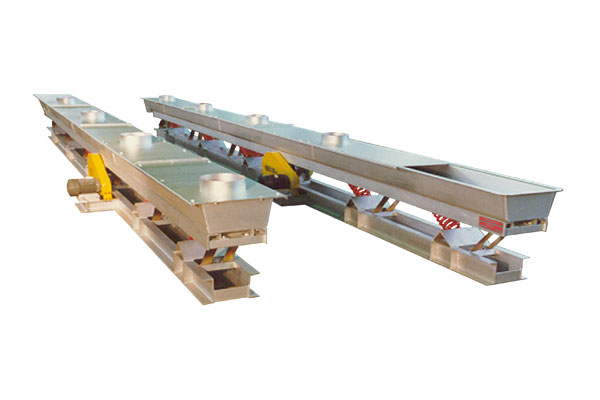

Our linear vibrating screens absorbs German advanced technology with unique eccentric structure. It is widely used in plastic, abrasive, chemical, pharmaceuticals, building materials, foods, carbon, fertilizer, refractory material, light industry, mining, coal, and other industry as well as selection and classification of powdery granular materials.

Feature and Advantages:

- Using block eccentric as excitation force, strong exciting force

- Using high strength bolts without welding

- Simple structure, convenient maintenance

- The use of tyre coupling, flexible connection, and smooth operation

- High screening efficiency, large capacity and long life

- Through year of production practice, it proves that straight line vibrating screen is capable of handling a large amount of material, reasonable technical parameter, structural strength, high stiffness, serialization, universal, high degree standardization, smooth and reliable operation, low noise, easy maintenance, and overhaul and a series of advantages.

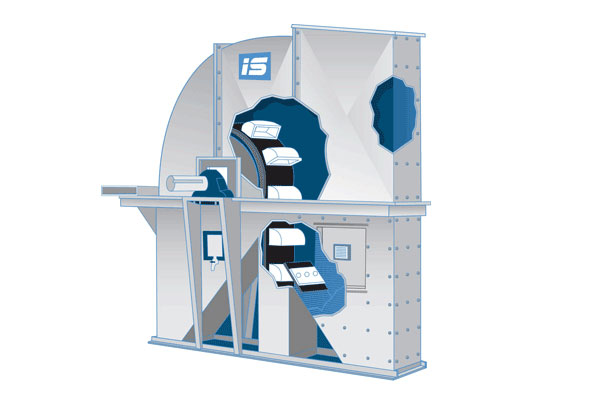

Metalfab industries offers a complete line of in channel or in tank screening system. Each unit utilizes a perforated sheet or v-wire screen section to effectively remove unwanted solid and debris from the influent. The screenings are transported via a conveyor to the compactor and washing zone, where they are cleaned dewatered then finally discarded into a receptacle or optional bagging system. Hi Tech Custom design each screening system according to the project requirement, screens can be installed in channel or in a self contained steel tank.

- Fine mechanical waste water, that contain hard to detect solid like feature, fur wool by means of perforated screen filtering mesh

- Absence of a numerous moving parts make the screw screen easily operated and reliable: all functions are performed by one screw.

- Screenings compacting inside the screen excludes additional dewatering equipments

- Screening washing allows to preserve organic compounds in waste water that further improves a biological treatment process.